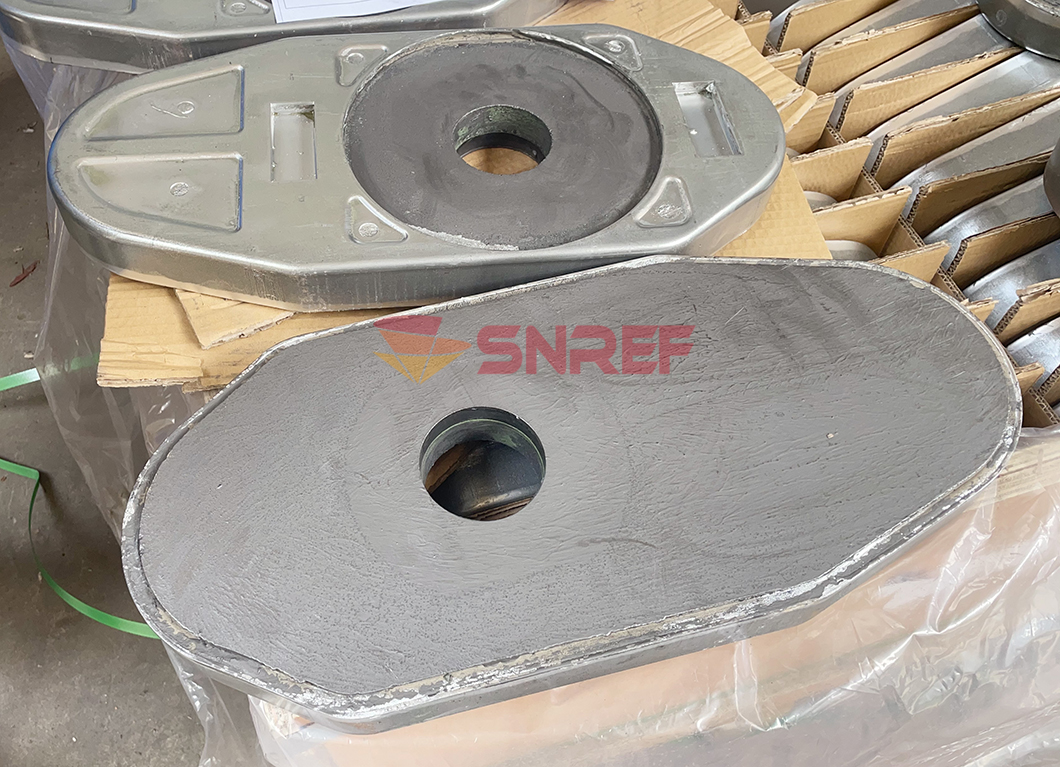

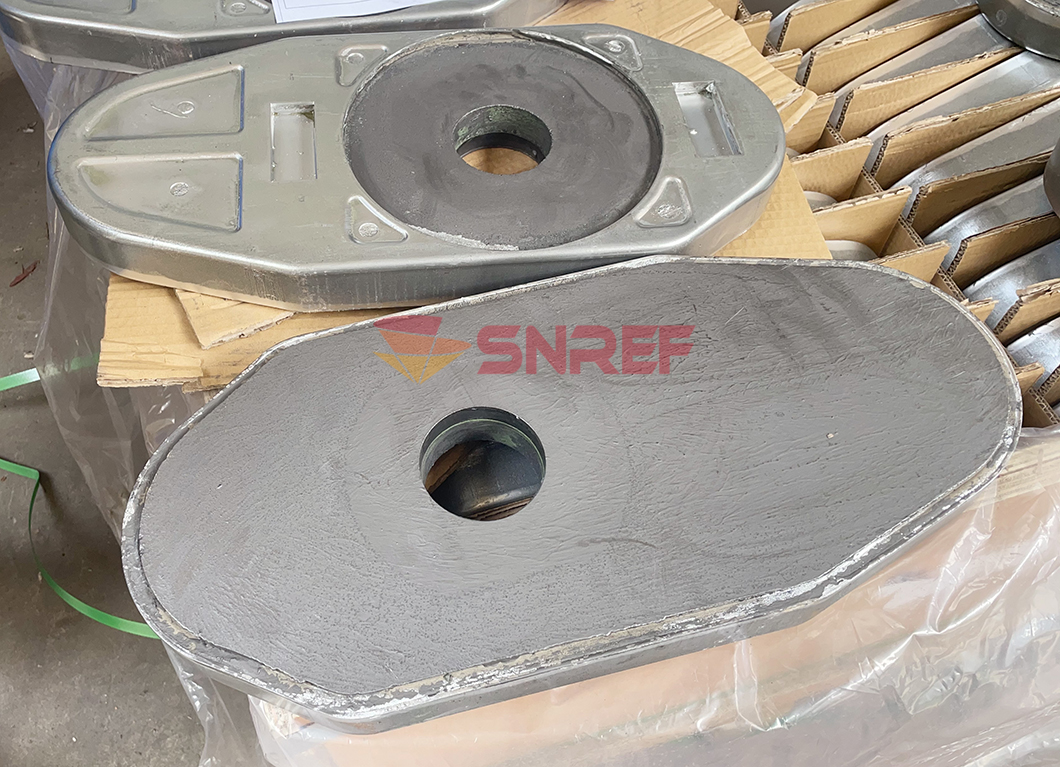

Deep burnt Alumina Zirconia Carbon Slide Plate

Slide gate plate is the key part in the slide gate systems. Function is to control the flow rate of molten steel.

The slide plate is exposed to high temperature molten steel repeatedly, especially the cast hole part, the erosion is serious,this require the slide plates obtaining features of High strength, excellent corrosion resistance, anti-stripping, to ensure no steel leak during pouring process.

Alumina-carbon, alumina-zirconia-carbon, magnesia-alumina-spinel slide gate plates and corundum, alumina-carbon, mullite, magnesia-alumina-spinel upper and down slide nozzles are made of quality materials with phenolic resin binder through pitch impregnation in vacuum and mid temperature treatment.

They are classified into high temperature sintered and unburned products.

The products have the good thermal stability, erosion resistance to molten steel, corrosion resistance and long service life. They are widely used in 20-300t steel ladles and various tundishes to well control flow rate of molten steel with safety and easy switch.

The features of Slide gate plates:

1. Flatness of sliding surface ≤0.05mm

2. High mechanical strength

3. High resistance to contamination of molten steel and slag

4. Excellent oxidation resistance

5. Good thermal shock stability

The seal protection for slide gates are mainly for upper slide plate and upper nozzle, lower slide plate and lower nozzle.

After one or two times of casting, lower slide plate and nozzle must be replaced and re-installed. The sealing materials could be gaskets made of fiber or fireclay. To ensure the high cleanliness of molten steel and the uniformity of internal quality of slab.

Deep burnt Alumina Zirconia Carbon Slide Plate

Adopting tabular corundum, fused alumina, fused alumina zirconia, zirconium mullite as raw materials, through the addition of moderate micro and fine metal powder, by reaction under high temperature, to increase the high temperature performance of plates. Through the adding of moderate boron carbide powder to increase the oxidation resistance of plates. The bonding agent is phenolic resin with high solid content and high carbon residue.

After forming, adotping advanced heating treatment technology, through impregnating, burning to form high performance slide plates. With features of good thermal stability, excellent erosion resistance, stable consistency in shape and size, mainly suitable for ladles over 180 tons or converter slagging slide gate systems.